The Government of Canada is taking important steps to help transition Canada to net zero with cleaner sources of energy. One of those steps included investing in Westinghouse’s eVinci™ microreactor, a small nuclear battery capable of providing 8 years of uninterrupted clean safe electricity.

The eVinci microreactor’s 5MWe can power more than 3,000 homes without the need for any water sources, ideal for empowering remote communities and unlocking additional value from new and existing industrial projects across Canada.

Westinghouse is powering ahead with its eVinci microreactor in Canada, building not only on our Canadian-based engineering and manufacturing expertise, but also on the investment by the Government of Canada and collaboration with leading Canadian nuclear suppliers. The impact of this contribution is real and evident, spurring us forward towards the goal of eVinci commercialization and deployment in Canada.

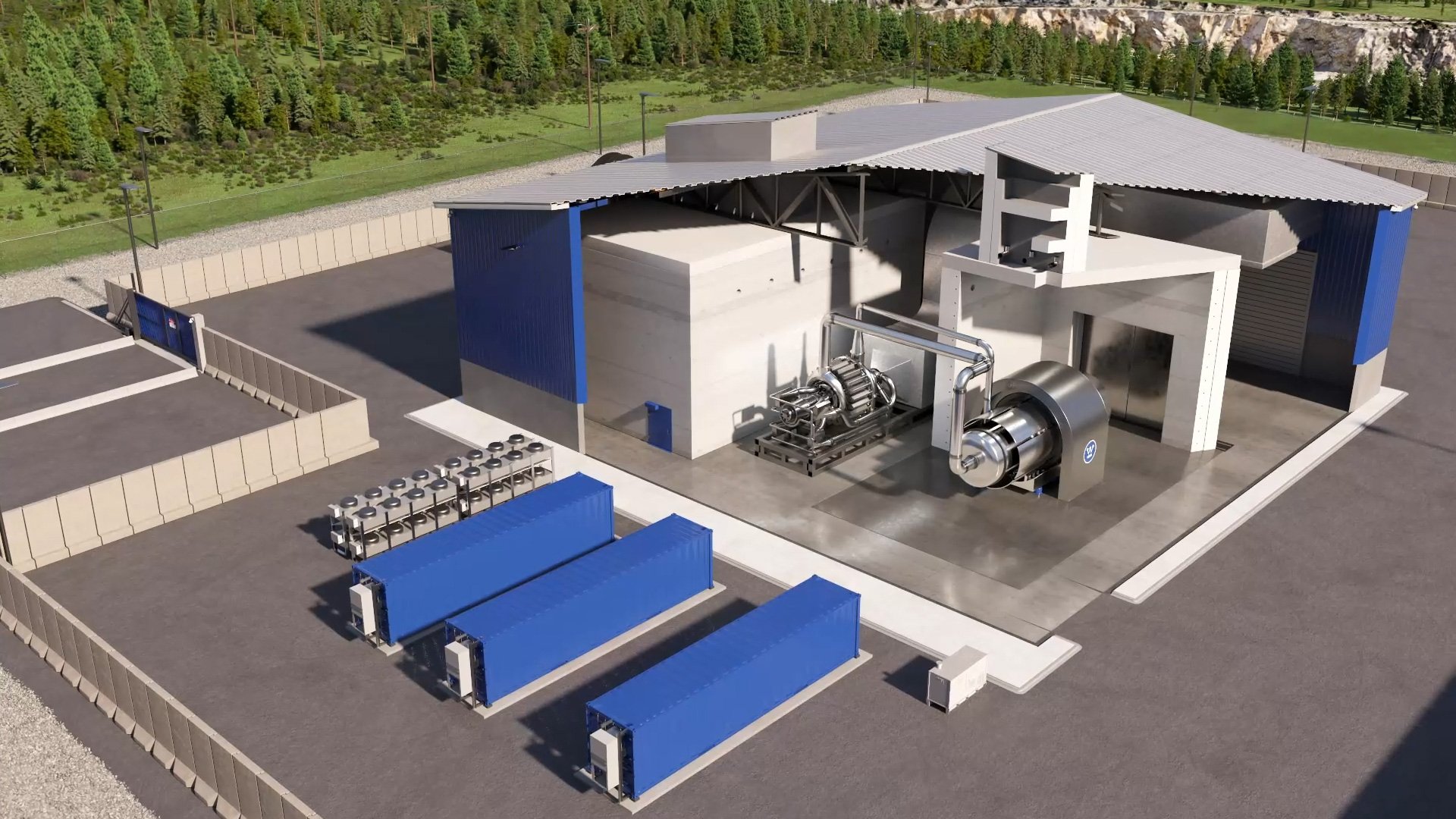

The eVinci microreactor from Westinghouse can help achieve deep decarbonization by safely and reliably replacing transported diesel fuel at remote locations, such as mining operations.

The eVinci microreactor from Westinghouse can help achieve deep decarbonization by safely and reliably replacing transported diesel fuel at remote locations, such as mining operations.

Impact of Canadian Government investment through the Strategic Innovation Fund

The Ministry of Innovation, Science & Economic Development’s investment through the Strategic Innovation Fund kickstarted Canada’s contribution to the research & development of the eVinci microreactor, tapping into the incredible talent across our growing Canadian offices and extending to Canadian partners within our ever-deepening supply chain.

In the 18 months since this historic investment began, our eVinci development program has snowballed with significant progress that is taking our technical readiness to a new level. Within Westinghouse Canada, the following achievements are bringing the eVinci closer to full demonstration in reactor components and deployment readiness.

The control drum for the eVinci microreactor is an essential component, allowing for autonomous changes in reactivity that can enable load-following or the shutdown of the reactor. Through demonstrations we have validated the component and assembly installation sequence, control methods, along with shutdown and safety systems. These demonstrations simulated the control methods and motion of a full-scale commercial control drum.

Another crucial component is the shutdown rod assembly. Here, too, our demonstrations have been successful. Testing provided insight into the mechanics and component strength required to successfully retrieve an absorber rod, along with release with sufficient energy. All information will be leveraged for developing the shutdown rod assembly for the Nuclear Test Reactor to be located at Idaho National Lab.

The eVinci team at the Peterborough facility during shutdown rod assembly testing.

The eVinci team at the Peterborough facility during shutdown rod assembly testing.

The fabrication of the majority of machined components, and of all welded assemblies, is taking place in our Peterborough, Ontario machine shop, with select components machined from our local vendors.

These assembly and testing activities have provided key insights into the interaction of components within the reactor system and will be leveraged to support the final design for our Nuclear Test Reactor. The data collected will help improve simulation and calculations for design refinement.

Our Partners in the Canadian Supply Chain

Westinghouse is dependent on the subject matter expertise of our partners within Canada’s world-class supply chain, both from within and beyond the nuclear industry, reaching into traditional and novel companies. Although we are only getting started in deepening the collaboration and partnerships, Westinghouse would like to acknowledge the contributions of several of our Canadian impact partners, which have been expedited by the SIF funding, including:

Canadian Nuclear Laboratories – executing a comparative review of Canada and US cyber security regulations for nuclear power plants and for support in the initial testing of Burnable Absorber Applications and Compact Fabrication.

Prodigy Clean Energy – providing licensing support in the evaluation of eVinci deployment model options and feasibility studies for Transportable & Terrestrial Nuclear Power Platforms (TNPPs).

McMaster University – completed material properties literature review along with corresponding material handbooks to inform engineering design and determination of future testing needs.

Saskatchewan Research Council – completion of a stakeholder engagement plan and initial site requirements findings.

Hatch – providing conceptual and detailed design of a Microgrid Interface System (MIS) and evaluation of various operational models that will support Westinghouse in our strategic efforts to pursue the highest priority and best-fit end customers.

Precision Specialized Inc. – executed an eVinci transportation logistics study based upon strategic North American deployment sites.

March Consulting – supporting creation of Provincial Environmental Assessments Roadmaps.

With the support of partners like these, we will drive the technical and commercial success of our eVinci microreactor program, across Canada and internationally, and to the final frontier of space. Special thanks to the Canadian Nuclear Association, Organization of Canadian Nuclear Industry’s Ready4SMR Program, and SIMSA for their leadership in supporting companies that will make the Natural Resources Canada SMR Roadmap a reality.

Westinghouse looks forward to collaborating with additional subject matter experts as the eVinci microreactor continues to build momentum towards demonstration, licensing, and deployment as the first commercialized microreactor in Canada.