Replacement of obsolete components provides improved performance and secures future product availability

The Challenge

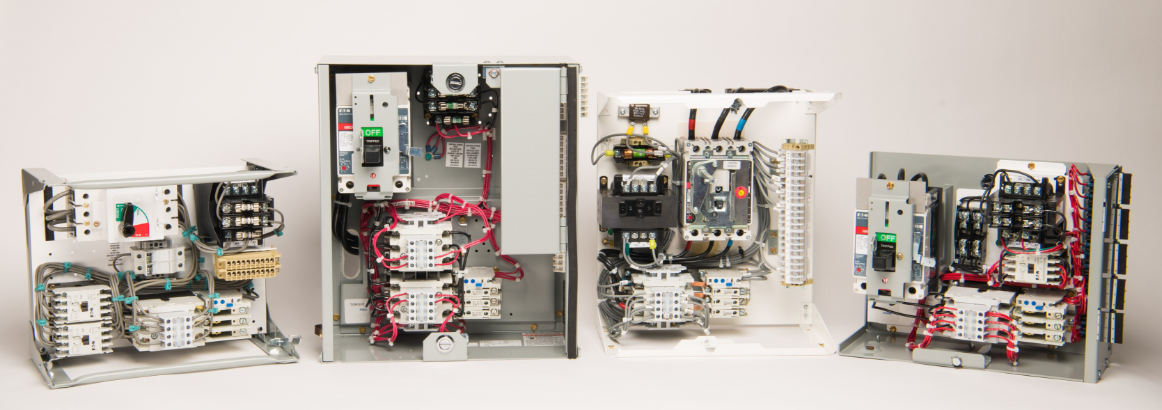

Entergy’s Grand Gulf Nuclear Power Station needed to replace numerous Klockner Moeller Motor Control Center (MCC) buckets that had reached the end of their lifespan. However that specific bucket design had since become obsolete, putting Entergy in the difficult situation of identifying a replacement that met the same operational standards with minimal impact to cost and schedule.

Our Solution

Westinghouse manages a part obsolesce program to supply or build numerous MCC bucket designs. Although Grand Gulf leveraged MCC buckets manufactured by another OEM, our experts utilized reverse engineering techniques to design and produce replacements that meet performance requirements without comprising quality standards.

Our drop-in designs provide “like for like” replacements that improve performance and reduce maintenance costs with minimal delivery, engineering and installation impact. We have qualified many of the individual components within the buckets to ensure future part support. Additionally, we offer inventory stocking programs that manage part security and costs associated with MCC bucket repair support.

The Impact

Entergy will soon receive the replacement buckets that will allow them to continue to operate safely and reliably. Additionally, the security of supply for future part support has been strengthened.