Delivering enhanced fuel reliability today for tomorrow’s operating fleet

Ensuring nuclear energy remains a cost-competitive source of carbon-free energy is the key focus of nearly every nuclear utility across the globe. There are countless evolutionary initiatives to enhance current performance, reduce O&M costs and increase plant efficiency. While those advancements are crucial, some stakeholders are beginning to think about a step-change in the way nuclear plants operate all together, especially as it relates to traditional fuel cycles.

A shift to 18- to 24-month fuel cycles would not only result in fewer plant outages, but provide utilities with improved fuel reliability and operating margins. There are several paths to this transition, with some requiring additional regulatory approvals for select technologies. Our teams have been at the forefront of this effort, designing and developing innovative fuel solutions that provide you with near-term benefits without adopting additional initiatives, such as higher burnup and enrichment levels.

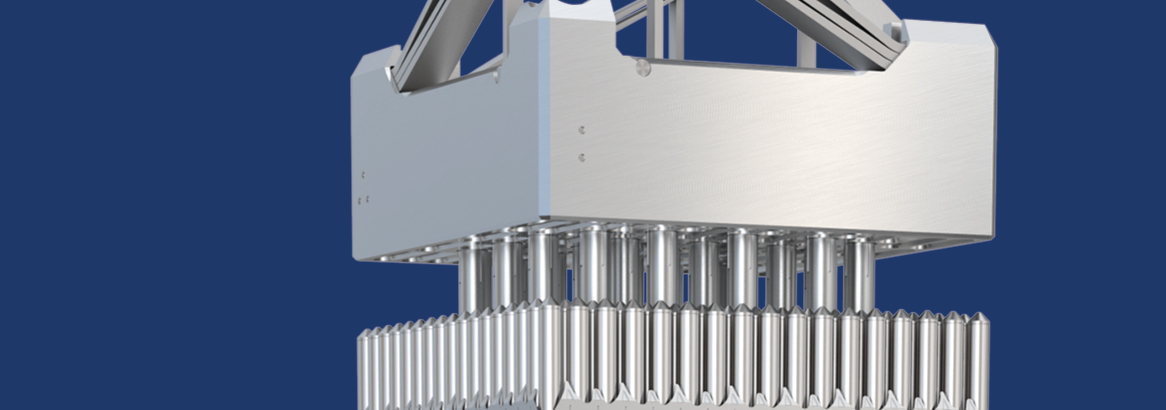

- PRIMETM Fuel - PRIME fuel’s advanced features include a reinforced dashpot, Low Tin ZIRLO™ grid straps material and a lower pressure drop bottom nozzle with enhanced debris protection

- ADOPTTM Fuel Pellets - Westinghouse’s ADOPT high-density fuel is a direct replacement for standard uranium dioxide (UO2) fuel and provides enhanced fuel pellet properties to enable improved fuel cycle economics, higher burnups and improved accident tolerance

- AXIOM® Fuel Cladding - Next-generation AXIOM fuel rod cladding is focused on delivering a cladding material targeted at high-duty operations in aggressive conditions with corrosion and hydrogen pickup performance superior versus alternate cladding solutions. The chemical composition for both our AXIOM and Optimized ZIRLO cladding has been optimized to avoid spallation and nodular corrosion issues for a wide range of operating environments. AXIOM cladding has been developed from a base of well understood alloying elements known to provide manufacturing process robustness.

By developing flexible and economical solutions that meet the changing needs of the industry, utilities can rely on Westinghouse for a tailored approach to achieving 24-month fuel cycles.

Key Benefits

- Reduce the number of required refueling outages

- Enhance fuel reliability and operating margins

- Commercially-ready technologies provide additional performance and cost benefits

- Avoid negative impact to peak cladding temperatures