Westinghouse and PSEG Use Innovative Approach to Tackle Major Industry-First Technical Challenge

The Challenge

During a scheduled refueling outage in 2019 at Salem Unit 1, our field personnel identified four failed thermal shield support block bolts (TSSBBs) and cracks on the outer welds of two thermal shield flexures. Additionally, fuel assembly grid strap damage was observed during core offload at two peripheral fuel assemblies.

This damage was found to be due to protruding baffle-former bolt heads, and a subsequent inspection of the bolts identified 232 new UT indications. This level of degradation was unexpected since, during a previous outage, the baffle-former bolts were inspected and 189 of the 192 bolts with indications were replaced. The failure of 232 additional original baffle-former bolts over two cycles represented an accelerated level of degradation that did not match industry OE for typical irradiation-assisted stress corrosion cracking (IASCC) in baffle-former bolts.

Our Solution

Due to the significant and unexpected level of degradation, our teams developed a collaborative approach with PSEG’s teams to perform investigative engineering analyses, monitoring and testing to determine if there was an underlying source to the degradation. Because Salem 1 was already in operation, our technical experts recommended utilizing neutron noise monitoring so they could determine the source – a first-of-a-kind approach for the nuclear industry.

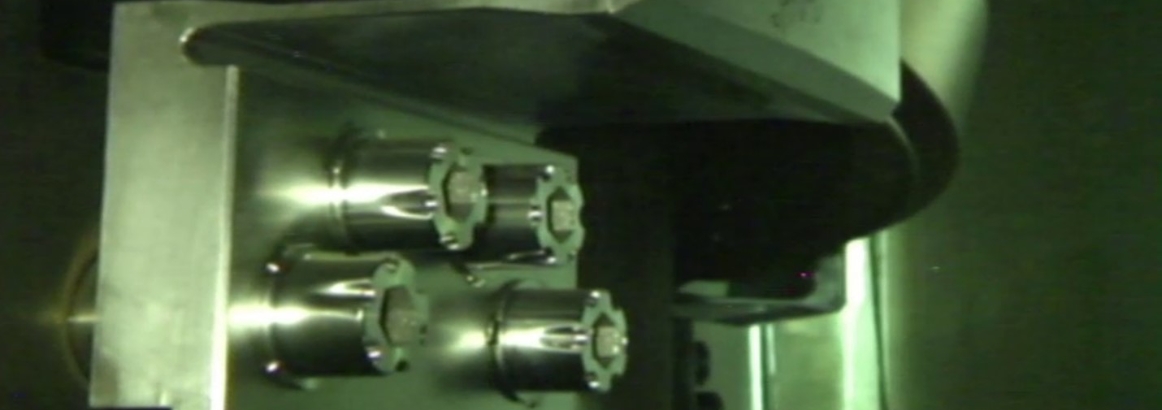

Through detailed analytical modeling of the reactor vessel internals and the inventive use of neutron noise monitoring, our team predicted thermal shield flexure degradation at Salem Unit 1 that was ultimately confirmed via inspection. Because this discovery was made during the fuel cycle rather than in outage, Westinghouse had time to develop, qualify and test a replacement prior to the next outage. When the outage came, personnel were well prepared to carry out the complex repairs that took place more than 30 feet underwater using remote tools to replace the flexures that are part of the lower reactor internals assembly.

The Impact

By leveraging neutron noise monitoring, the project team team went from having anomalous data at the plant (with no idea of the cause) to predicting the cause, designing and manufacturing a replacement flexure and associated tooling, and installing it – all within the span of nine months. Most importantly, the replacement of the degraded reactor vessel internals will help ensure the long-term and safe operation of Salem 1.

Key Statistics

- Lifecycle of thermal shield flexure replacement completed in just nine months

- This first-to-market innovative design and tooling can be used to greatly reduce the impact of flexure degradation identified at any of the roughly 30 Westinghouse plants with thermal shields

- Visual inspections confirmed that five of the eight thermal shield flexures were found to be completely severed

- Significant schedule and cost savings from early preparation