Advanced manufacturing technologies provide design freedom and reductions of cost and lead-time.

Designs are the language of innovation, and engineers are the linguists. The freedom to imagine and create solutions can lead to inspired creations that have not previously been possible.

In an industry controlled by parameters and regulations, nuclear engineers must often find a delicate balance between evolution and revolution to offer practical and cost-effective innovations. But as manufacturing technologies become more advanced, those barriers start to open and reveal exciting new paths.

Through state-of-the-art techniques like 3D printing and diffusion bonding, we are developing and deploying advanced manufacturing technologies to realize cost and lead-time reductions, and enable next-generation solutions for energy generation. In the spring of 2020 Westinghouse became the first to install a 3D-printed component inside of a nuclear reactor. Now we’re setting our sights on the next milestone – installing an additively manufactured fuel component.

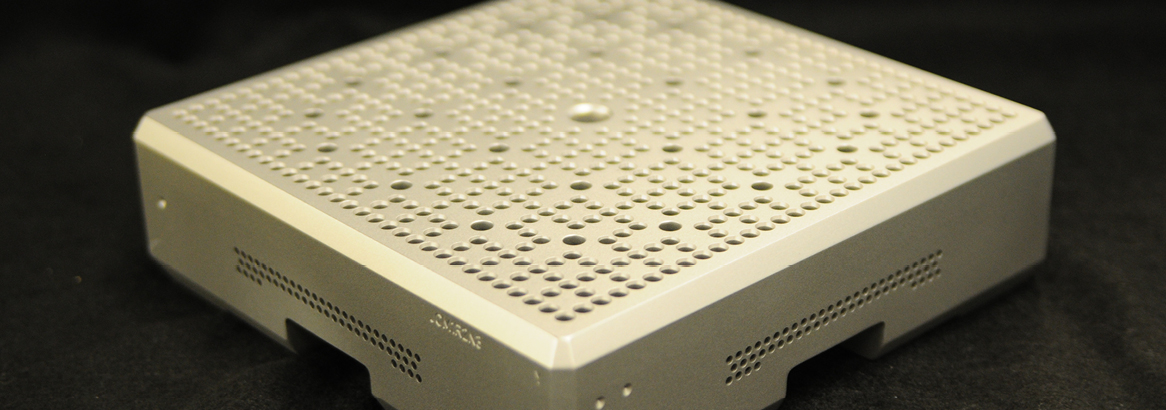

Following the success of debris mitigation features in our PRIME package, and in order to further enhance benefits, we’re planning to use advanced manufacturing techniques to maximize debris protection, and reduce costs and lead-times for a fully optimized bottom nozzle. Our technical experts are finalizing the advanced debris filter bottom nozzle (ADFBN) design, which could be implemented in a commercial reactor as soon as 2022. Our 3D-printed ADFBN demonstrates the progression of additive manufacturing in the nuclear industry, and is a crucial step towards addressing the need for a wide variety of low-volume, highly critical plant components.

Key Benefits

- Industry-leading debris mitigation

- Reduced manufacturing cost and lead time

- Achieves mechanical properties comparable to conventional wrought materials

- Produced with readily available metal powders

Learn more about our advanced manufacturing program and our PRIME fuel package.