Engineering expertise and responsive services reduced the risks tied to aging components and minimized the cost of equipment failures.

The Challenge

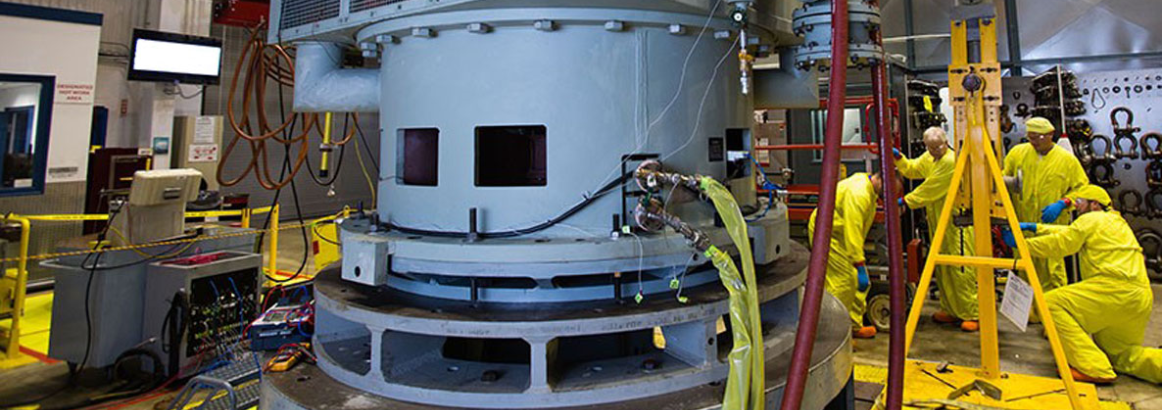

While operating through a normal fuel cycle, a U.S. utility had indications of compromised operation for one of their reactor coolant pumps (RCPs). During the next scheduled refueling outage, field personnel inspected the RCP in question and observed signs of bearing failure. With the combined performance data and inspection results, it was determined that the pump needed to be replaced to avoid operational challenges or a forced plant shutdown.

Our Solution

Westinghouse quickly mobilized a skilled RCP crew to site to advise and augment the existing outage team. In addition to the field service support, our engineering teams validated utility spare pump readiness for use and ensured all appropriate documentation was complete for the change. The RCP was removed and a spare was installed within 14 days from customer notification, resulting in minimal impact to the overall outage critical path.

After receiving the compromised RCP, our Pump & Motor Shop decontaminated, disassembled and thoroughly inspected the removed RCP and found that the radial bearing graphite had failed, spreading graphite particles throughout the RCP components. While thermal barrier replacement (due to foreign material intrusion) was the most likely resolution, Westinghouse worked to develop an inventive solution to clear the thermal barrier of the failure debris without necessitating replacement.

The Impact

Ultimately, the thermal barrier was thoroughly cleared of foreign material and the RCP was reassembled with a new radial bearing and shaft to ensure a substantial future operating life. The responsiveness and innovative thinking of our teams resulted in a minimized schedule and cost impact, as well as a multi-million dollar reduction in potential sub-component replacement. Additionally, the utility was able to avoid a potential two-year lead time they would have needed to operate without a viable spare RCP.

Key Statistics

- Immediate Westinghouse mobilization resulted in a 14-day window from customer notification to successful installation, avoiding significant critical path impact

- Multi-million dollar reduction in component replacement

- Avoided two-year period of operations without a viable spare RCP