Westinghouse continues to advance cutting-edge innovations inside fission reactors, including producing clean hydrogen for fuel and radioisotopes for cancer treatments. Recently, we have taken our industry-leading expertise in fission to support the design of a fusion reactor being developed in France.

Westinghouse joined a consortium with Ansaldo Nucleare and Walter Tosto to design, manufacture and deliver pieces of France’s ITER reactor, one of the world’s largest international fusion experiments. Countries and companies across the globe are contributing to the project of building the world’s first commercial-sized fusion reactor.

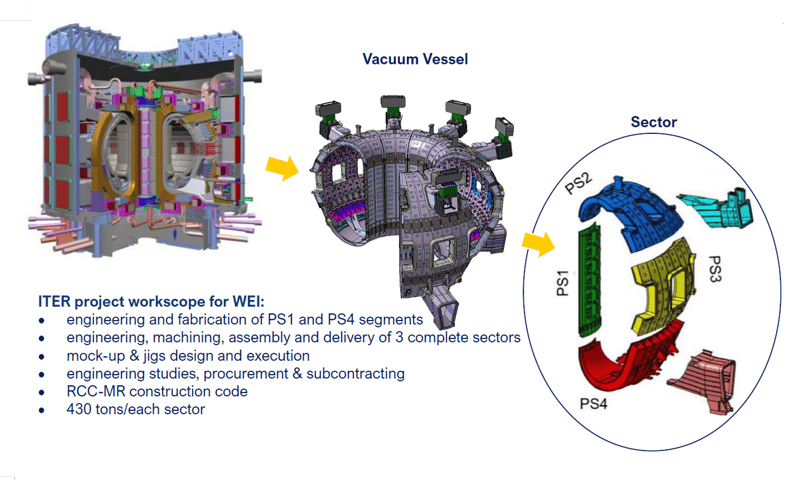

Our partnership is responsible for five of the nine sectors of ITER’s massive vacuum vessel and is being managed by Fusion for Energy (F4E).

Westinghouse subcontracted our longtime partner Equipos Nucleares S. A., S.M.E., (ENSA) to fabricate three PS1 and three PS4 segments for the ITER project. Westinghouse acted as the design authority, providing ENSA with engineering, tooling and procurement support. In the fabrication of the PS4 segments, ENSA developed and implemented a robot-based automatic welding process that enhanced the quality of the welds.

ENSA recently completed and shipped the last vacuum vessel segment in their scope to Westinghouse’s facility in Monfalcone, Italy. The segments will be assembled to form a larger sector piece of the fusion vacuum vessel. The ITER reactor’s circular vacuum vessel is a toroid formed by nine sectors. The vessel will house the fusion reactor plasma.

The sector that Westinghouse Mangiarotti delivers to the reactor construction site in France will be the first of the consortium’s contribution to the ITER project.

“Westinghouse is proud to have the opportunity to work on a project that potentially holds the key to a new source of clean energy for future generations,” says Luca Oriani, Westinghouse Senior Vice President and Global Chief Engineering Services Officer. “The ITER project realizes an unprecedented global cooperation of industry, government, and research institutions. We are especially proud of our cooperation with our partners Ansaldo, ENSA, and Walter Tosto under the leadership of F4E.”

On behalf of Fusion for Energy (F4E), Cristian Casanova, said that “the completion of this milestone reinforces the commitment of the stakeholders to the values of the project, which could be summarized as trust, team spirit, action, and resilience.”

“ENSA is proud to have collaborated in this project, which has allowed us to be at the international technological forefront. The technical developments we have undertaken and implemented throughout this ITER project, have strengthened two fundamental pillars of our strategy: maintaining a technological differentiator and being the support of all our clients worldwide,” ENSA Vice president Operations, Design and Projects, Miguel Angel Anderez said. “This experience has reinforced our confidence to overcome any challenge by applying our continuous learning and improvement process acquired throughout our 50-year history. We deeply appreciate the trust that the different members of the project, Westinghouse, AMW and F4E, have put on us during these years, and we look forward to the next opportunity to work together.”

“ENSA is proud to have collaborated in this project, which has allowed us to be at the international technological forefront. The technical developments we have undertaken and implemented throughout this ITER project, have strengthened two fundamental pillars of our strategy: maintaining a technological differentiator and being the support of all our clients worldwide,” ENSA Vice president Operations, Design and Projects, Miguel Angel Anderez said. “This experience has reinforced our confidence to overcome any challenge by applying our continuous learning and improvement process acquired throughout our 50-year history. We deeply appreciate the trust that the different members of the project, Westinghouse, AMW and F4E, have put on us during these years, and we look forward to the next opportunity to work together.”

Here is a look at the history of the ITER project, and the countries involved.

Read more about Europe’s contribution to ITER, and about the robotic welding techniques used by ENSA.