Top Innovative Practice (TIP) Award demonstrate Westinghouse’s leadership in steam generator services and technology

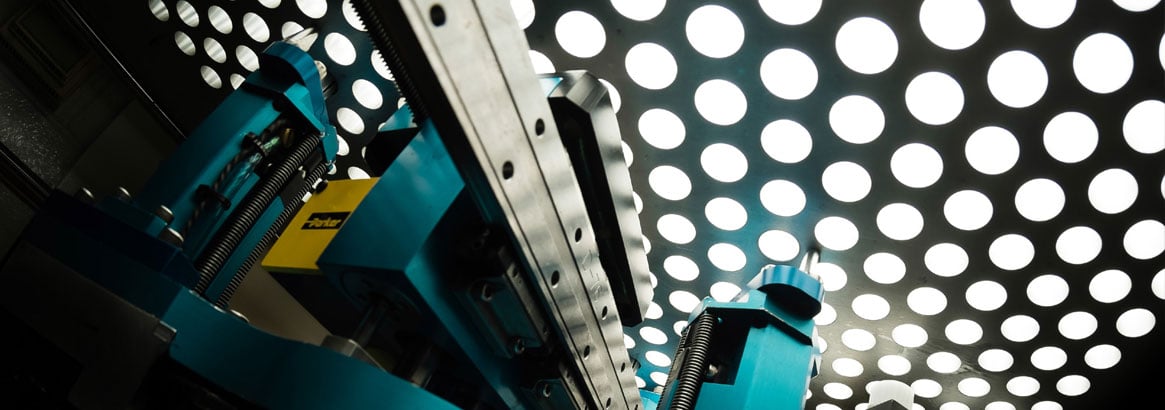

(About the above photo)

Westinghouse’s Pegasys® robot, paired with our latest technologies for inspection and analysis, Zephyr® Advanced Acquisition System and TITAN™ Automated Analysis Platform, equate to safer inspections, higher quality data, shorter outage times and lower costs.

Steam generators are vital plant components. Even with the best care, they require careful monitoring and maintenance to protect them from corrosion and other damaging impacts from their operating environment.

That’s where Westinghouse’s Zephyr® Advanced Acquisition System comes in, providing plant operators with significant savings in cost and dose during outages, or routine steam generator maintenance. The Zephyr system is a steam generator tubing inspection system designed to optimize steam generator eddy current inspection, helping to ensure steam generator tubes aren’t degraded. The Zephyr system is comprised of several components, with each segment redesigned to maximize its efficiency:

- Advanced robotics are used to position inspection probes at the correct location in the steam generator for tubing inspection.

- A sealed inspection probe delivery system component uses air assist to drive the inspection probes through the tubes.

- The third component of the Zephyr system is the Zephyr inspection probe itself.

- Finally, all of these individual Zephyr system components are brought together with software, which was specifically developed to optimize this inspection technology. The software controls robot speed and positioning and also contains variable speed probe control.

We’re proud to protect our customers’ investments and extend plant licenses while supporting the industry’s unified mission to continually improve its exemplary record for worker safety.

Speaking of proud, we’re also pleased that our customer, Arizona Public Service Company’s Palo Verde site, was recently recognized with a Top Innovative Practice (TIP) Award, which demonstrates Westinghouse’s industry leadership for steam generator services and technology.

Arizona Public Service Company’s Palo Verde site worked closely with Westinghouse to employ the Zephyr® Advanced Acquisition system for its steam generator inspections during its spring 2015 outage. Using Zephyr, this site’s steam generator tubing examinations were completed in less than half the historical best time and at two-thirds of the expected radiation exposure.

The award was presented at Nuclear Energy Institute’s Nuclear Energy Assembly, which took place May 23-25, 2016 in Miami. Each year, the TIP Awards highlight the nuclear industry’s most innovative techniques and ideas, sharing fresh ideas and best practices and consequently improve safety, work processes and the competitive position of the industry as a whole. They all share one quality – impact, and we’re proud of the impact we’re delivering for customers and for the industry.