Västerås, Sweden – June 13, 2022 – Westinghouse installed its StrongHold® AM 3D-printed nuclear fuel debris filters in two Nordic Boiling Water Reactor (BWR) units – Olkiluoto 2 in Finland, and Oskarshamn 3 in Sweden – to further improve the plants’ operational reliability.

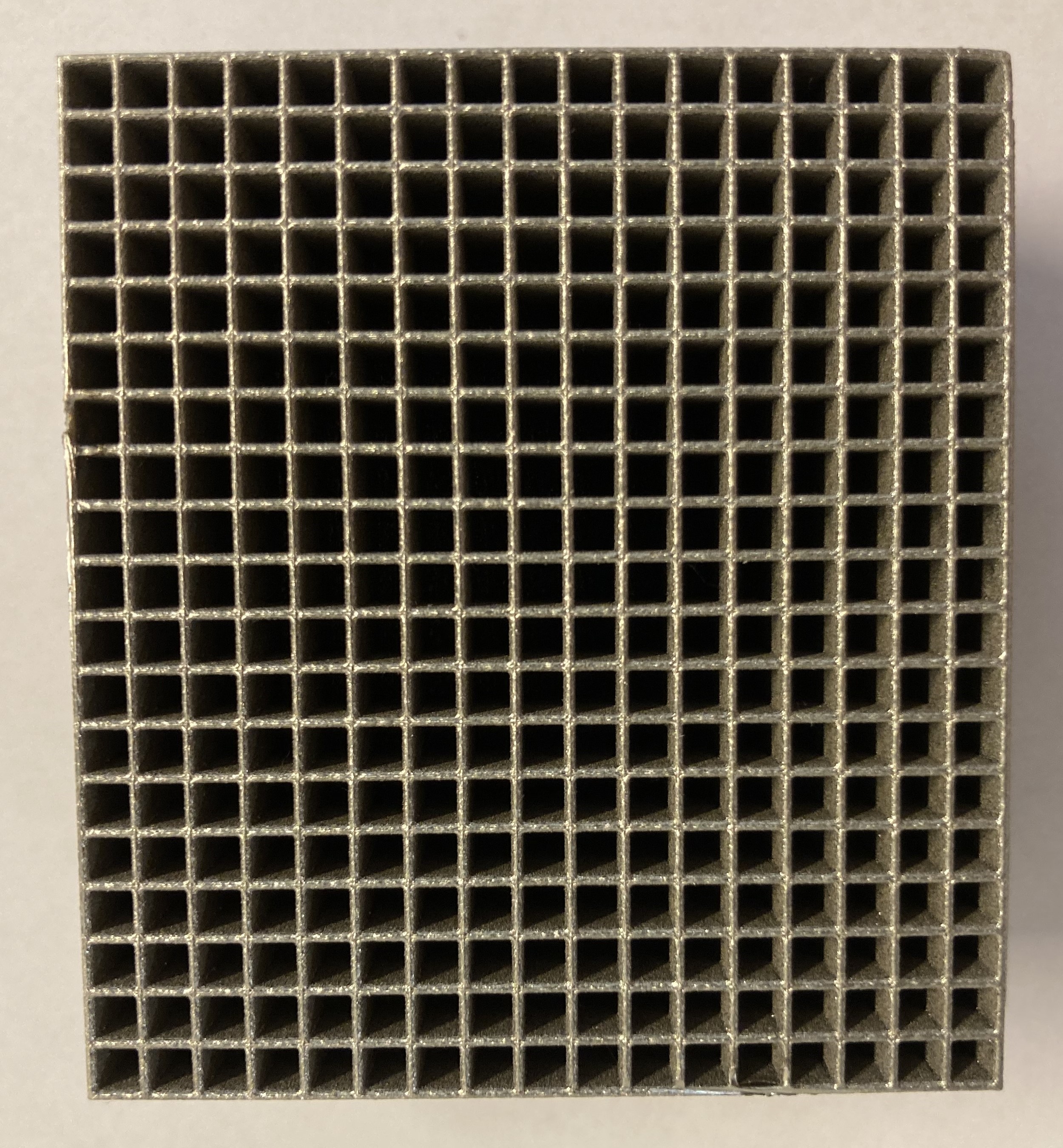

Westinghouse created the StrongHold AM filter in close cooperation with plant operators Teollisuuden Voima Oyj (TVO) and OKG. The StrongHold AM filters are fully manufactured through 3D printing techniques and offer enhanced capture features to prevent debris from entering the fuel assembly and potentially damaging the cladding, which could cause unplanned and expensive outages.

“We can now gain important practical experience in the use of 3D-printed metal products which will become an ever more important operational solution going forward. It is important to have a strong network of partners like Westinghouse who deploy additive manufacturing to drive enhanced capability,” said Arttu Knuutila, TVO Fuel Procurement Team Leader.

“Fuel damages can force us to temporarily suspend operations, which affects security of supply and entails unnecessary costs,” said Andreas Roos, Oskarshamn 3 Plant Manager. “Reducing the risk of fuel damages is very positive for our business.”

“As the first 3D-printed fuel debris filter for insertion in a nuclear power plant, the StrongHold AM marks a major milestone in our effort to further improve the BWR fuel reliability by leveraging advances in manufacturing technology,” said Dr. Carina Önneby, Westinghouse Vice President EMEA Fuel Delivery.