Milestone Manager Reveals Personal Motivation during the Final Stretch of Haiyang 1

Above: A major construction milestone is reached at the Haiyang Unit 2 AP1000 plant in China as the containment vessel top head – which consists of steel plates that are fabricated off-site and shipped to the project site for assembly – is placed.

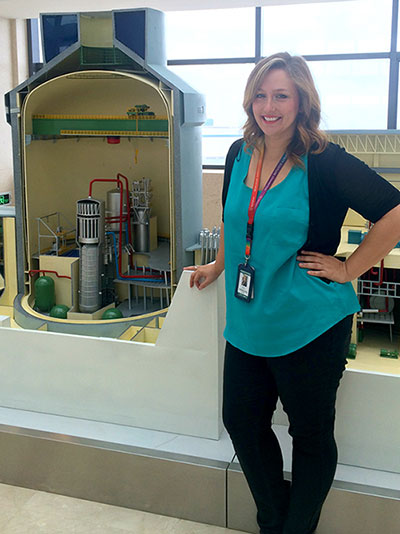

Allyson Mazzoni, shown here with a model of the AP1000® plant, first joined Westinghouse in 2007 as part of a Field Services team that performed refueling and fuel inspection work for U.S. plant outages, including loading and unloading fuel into the reactor vessel.

“When I first started at Westinghouse, I worked with a lot of people who had been doing this job for more than 30 years. They told stories about when they had started up some of the very plants we were working on,” said Allyson. “One guy – I remember it so clearly – showed me a picture of an initial fuel load he worked on. There were several assemblies already in the core. He was standing above of them, guiding them into place by hand.

“This absolutely amazed me because there he was, standing in a dry reactor cavity touching fuel as it went into the core. This is something you would never be able to do at operating plants because the cavity is flooded when you insert the fuel; it’s such a unique opportunity. That is when I knew that I wanted the same opportunity one day. That’s the reason I came to China, and that’s the reason I am still here.”

The world’s first AP1000 nuclear plants are nearing completion in China, with commissioning tests underway at Sanmen Unit 1 in Zhejiang Province and at Haiyang Unit 1 in Shandong Province. The hot functional test (HFT) is currently in process at both units, which is the final milestone before fuel is loaded into the units’ reactor cores.

Allyson Mazzoni is the Westinghouse milestone manager at Haiyang 1, currently focused on the HFT milestone. She is part of the team running the test, which is the dress rehearsal for the plant.

The HFT takes the plant through operating temperatures and pressures that it will experience once fuel is loaded and confirms that the reactor coolant system and all other associated systems will function as designed.

“These are the first AP1000 plant projects ever, and to be part of that is very special and something everyone should be proud of,” said Mazzoni.

She and her colleagues are establishing a new legacy in the nuclear industry with the most advanced, safest nuclear plant technology on the market today – the AP1000 plant. It is simply the art of innovation.

Learn more about what sets the AP1000 plant apart by clicking here.